Pakalka, S.; Valančius, K.; Čiuprinskas, K.; Pum, D.; Hinteregger, M. (2017). Analysis of possibilities to use phase change materials in heat exchangers-accumulators. In 10th International conference „Environmental Engineering“. Vilnius Gediminas Technical University.

We create great technology

Research and development of innovative energy storage technologies

Numerical modeling of the heat transfer process

Experimental research of the heat transfer process

Synthesis and characterization of new materials

Department Of

Energy Storage

Research and development of innovative energy storage technologies

Numerical modeling of the heat transfer process

Experimental research of the heat transfer process

Synthesis and characterization of new materials

Department manager: Saulius Pakalka

E-mail: s.pakalka@protechnology.lt

Publications

Pakalka, S., Valančius, K., & Damonskis, M. (2020). Effect of open and closed operation modes on the performance of phase change material based copper heat exchanger. In 11th International conference „Environmental Engineering“ 21-22 May 2020, Vilnius Gediminas Technical University, Lithuania (pp. 1–7). Vilnius: VGTU Press.

J. Doneliene, V. Ulbikaite, E. Urboniene, S. Pakalka, J. Ulbikas. Structural characterization of TiO2 aerogel vs precursor type and gel aging // 18th international conference on nanosciences & nanotechnologies: 5-8 July 2021, Thessaloniki, Greece: book of abstracts. Thessaloniki : [s.n.]. 2021, p. 176. [M.kr.: T 008]

Donėlienė, Jolanta; Ulbikas, Juras; Fataraitė-Urbonienė, Eglė. Influence of synthesis and subcritical drying conditions on the porosity of TiO2 aerogel // Advanced materials and technologies: book of abstracts of 23rd international conference-school, 23-27 August 2021, Palanga, Lithuania. Kaunas : Kaunas university of technology. ISSN 2669-1930. 2021, B-P166, p. 200. [M.kr.: T 008]

Presentations at Conferences

Pakalka, S.; Donelienė, J.; Rudzikas, M.; Valančius, K.; Streckienė, G. Development and experimental investigation of full-scale phase change material thermal energy storage prototype for domestic hot water, J. Energy Storage. (2024). https://doi.org/10.1016/j.est.2023.110283.

Donėlienė, J.; Fataraitė-Urbonienė, E.; Danchova, N.; Gutzov, S.; Ulbikas, J.. The influence of the precursor’s nature and drying conditions on the structure, morphology, and thermal properties of TiO2 aerogels // Gels, MDPI, 2022, vol. 8, , iss. 7, art. no. 422, p. 1-16. DOI: 10.3390/gels8070422

Donėliene, J.; Fataraite-Urboniene, E.; Rudzikas, M.; Pakalka, S.; Danchova, N.; Ulbikas, J. Effect of precursor nature and sol-gel synthesis conditions on TiO2 aerogel’s structure, Molecules. 26 (2021). https://doi.org/10.3390/molecules26165090.

Pakalka, S., Valančius, K.. Experimental investigation and prediction of charging/discharging performance of phase change material based thermal energy storage unit. Environmental and Climate Technologies, (2021)25(1), 600–609. https://doi.org/10.2478/rtuect-2021-0044

Projects

BIO insulation materials for Enhancing the Energy performance of Buildings (BIO4EEB)

EFFIHEAT-DEMO

EFFIHEAT

Infrastructure & Services

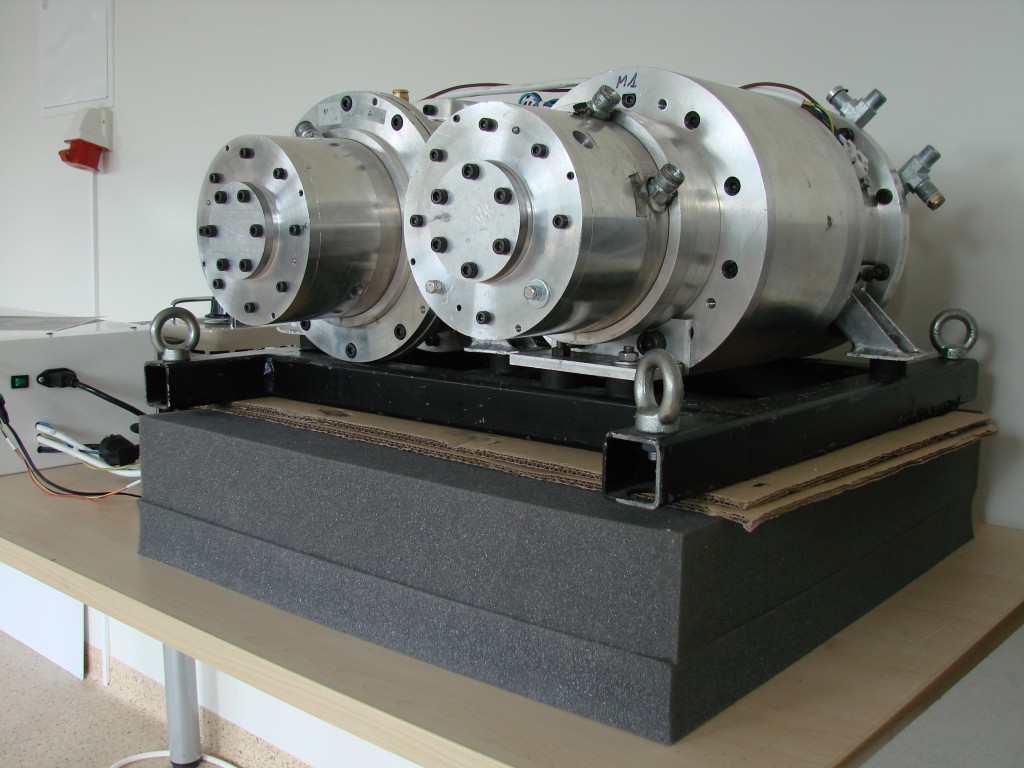

Description

Performance monitoring: temperature, pressure, mass flow rate, heat transfer rate, energy

Simulation of different thermal energy storage charging and discharging modes

Validation of analytical and numerical models

Technical specification

Coriolis mass flow rate meter, accuracy ±0.15%, maximum flow rate 1.81 kg/s

Temperature sensors PT100, class B, accuracy ± (0,3 + 0,005·t) °C

Pressure sensors for liquids and gases, maximum pressure 0-600 kPa, accuracy ±0.5%

Description

Phase change materials (PCMs) phase transitions and melting enthalpies determination

Technical specification

Temperature range: -180°C to 700°C

Heating rates: 0.001 K/min to 200 K/min